Short Lead Time for Filtering Strainer - Rubber Mixing Mill (Two Motors & Two Output) – Power

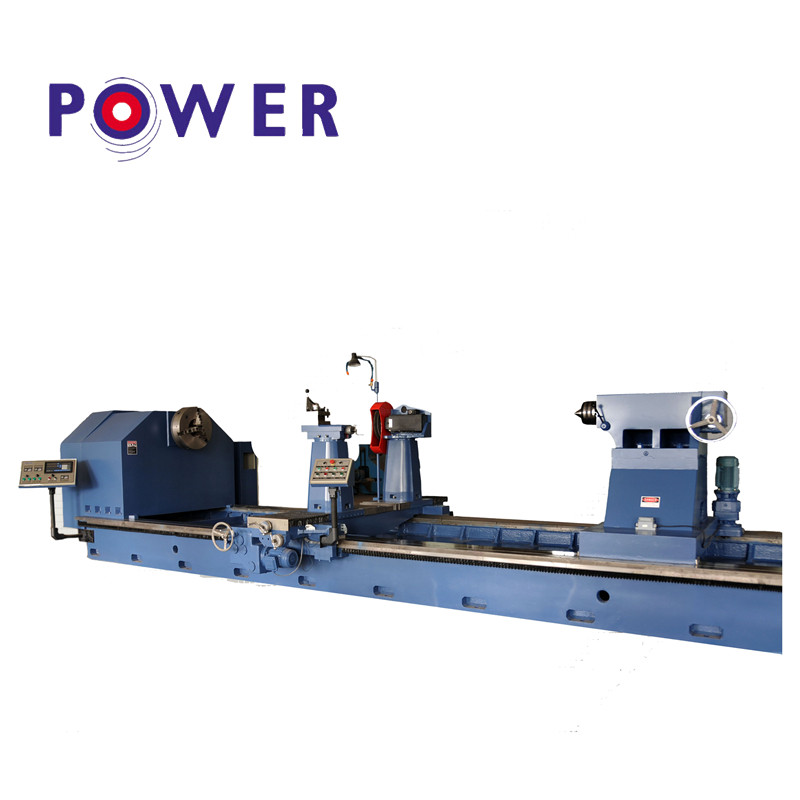

Short Lead Time for Filtering Strainer - Rubber Mixing Mill (Two Motors & Two Output) – Power Detail:

Product Feature

1. Made of high quality material

2. Easy installation directly on plain ground

3. Enforce cycle cooling system

4. Safe and efficient

Product Description

1. Enhance the intensity of the machine body by using more carbon steel and less wrought iron.

2. Machine can be placed on the plain ground directly, other installation method is unnecessary.

3. The roller bearing supports the heavy loading and high temperature. Using roll bearing double the size and use less lubrication oil, able to use longer and easy to maintain.

4. All the parts of the machine are processed by rust proofing with chromium, to prevent the key parts polluted.

5. Enforce cycle cooling system, enhance the cooling effect by using spin joint and enlarge pipe.

6. Using energizing mechanic power off system, guarantee the well and speedy function under the long term using.

|

Model |

φ14″ |

φ16″ |

φ18″ |

|

Roll Size (D/L) |

360*920 |

400*1060 |

450*1200 |

|

Linear Speed (M/Min) |

23.7 |

20.65 |

23.22 |

|

Front Roll RPM |

4-20 |

4-20 |

4-20 |

|

Roll Ratio (Front/Back) |

Free Adjustment |

Free Adjustment |

Free Adjustment |

|

Produce Weight(Once) |

20-25 KG |

25-35 KG |

30-50 KG |

|

Motor Power |

15KW X 2 Sets* |

30KW X 2 Sets* |

37KW X 2 Sets* |

|

Weight (KG) |

5800 |

8000 |

12800 |

|

Dimensions (LXWXH) |

3700*1425*1870 |

4000*1500*1870 |

4560*1670*2020 |

|

Bush |

Bearing Type |

Bearing Type |

Bearing Type |

|

Receiver Material |

Stainless Steel |

Stainless Steel |

Stainless Steel |

|

Cooling Mode |

Pressurized Cooling Rotating Joint |

||

|

Emergency Stop |

Press Button Brake & Foot Brake |

||

|

Transmission |

Low Noise Gear Box Gear |

||

|

* Motor Power can be customized by different material requirements. |

|||

|

Model |

φ22″ |

φ24″ |

φ26″ |

|

Roll Size (D/L) |

55*1530 |

610*1830 |

660*2130 |

|

Linear Speed (M/Min) |

28.29 |

31.6 |

34.2 |

|

Front Roll RPM |

4-20 |

4-20 |

4-20 |

|

Roll Ratio (Front/Back) |

Free Adjustment |

Free Adjustment |

Free Adjustment |

|

Produce Weight(Once) |

50-60 KG |

120-130 KG |

160-170 KG |

|

Motor Power |

75KW X 2 Sets* |

15KW X 2 Sets* |

15KW X 2 Sets* |

|

Weight (KG) |

18500 |

25500 |

32000 |

|

Dimensions (LXWXH) |

5370*1950*2200 |

6100*2050*2200 |

6240*3350*2670 |

|

Bush |

Bearing Type |

Bearing Type |

Bearing Type |

|

Receiver Material |

Stainless Steel |

Stainless Steel |

Stainless Steel |

|

Cooling Mode |

Pressurized Cooling Rotating Joint |

||

|

Emergency Stop |

Press Button Brake & Foot Brake |

||

|

Transmission |

Low Noise Gear Box Gear |

||

|

* Motor Power can be customized by different material requirements. |

|||

Services

1. On-site Installation service can be selected.

2. Maintenance service for life long.

3. Online support is valid.

4. Technical files will be provided.

5. Training service can be provided.

6. Spare parts replacement and repair service can be provided.

Product detail pictures:

Related Product Guide:

Our organization sticks to your principle of "Quality may be the life of your organization, and reputation will be the soul of it" for Short Lead Time for Filtering Strainer - Rubber Mixing Mill (Two Motors & Two Output) – Power , The product will supply to all over the world, such as: New Orleans, Macedonia, Madagascar, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.