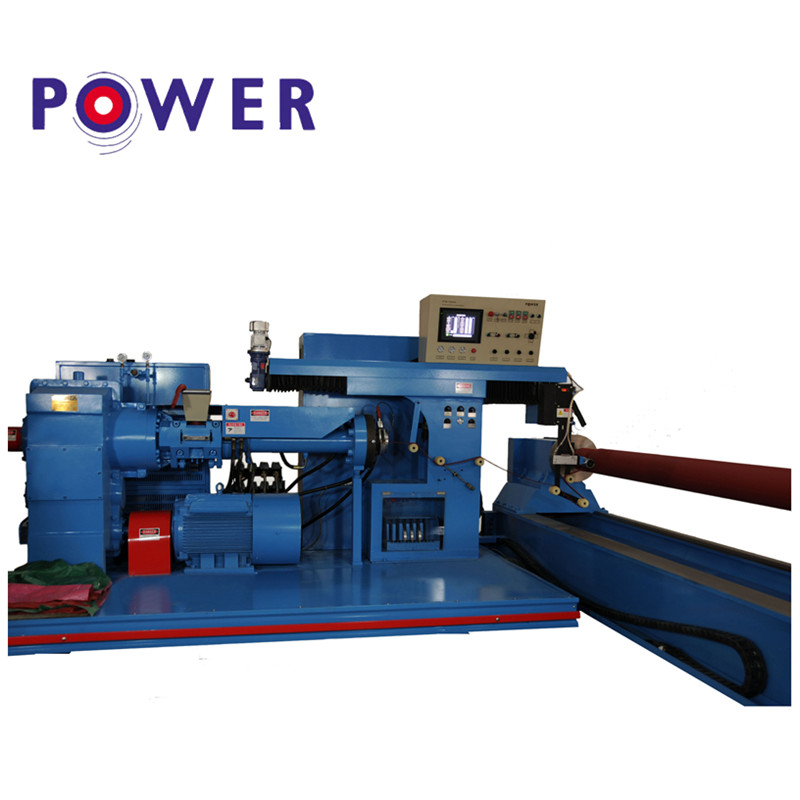

Rapid Delivery for Surface Lapping - Rubber Roller Covering Machine – Power

Rapid Delivery for Surface Lapping - Rubber Roller Covering Machine – Power Detail:

Product Description

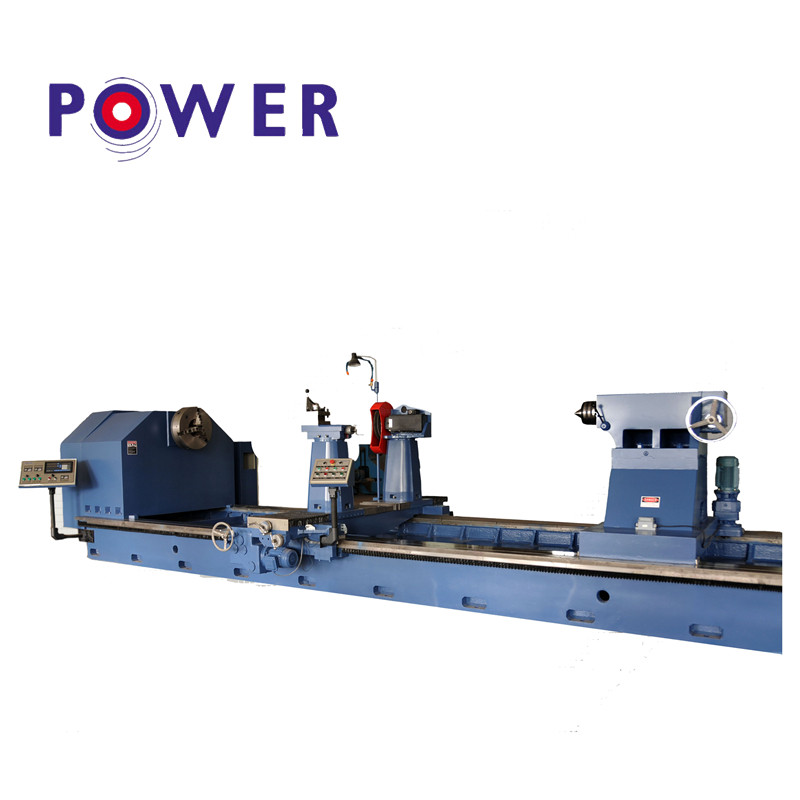

1. Applicable to the types of rubber roller processing:

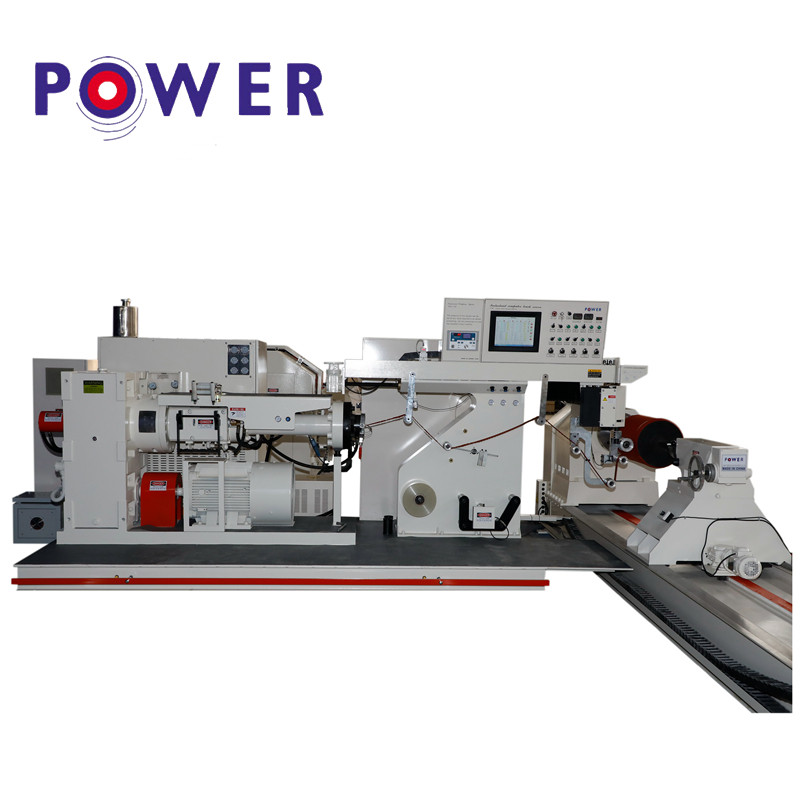

(1)The PTM-4030 & PTM-8060 models are suitable for rubber covering process on printing rollers, general industrial rollers and small industrial rubber rollers.

(2)The PTM-1060 model is suitable for processing general industrial rollers and small paper rubber rollers.

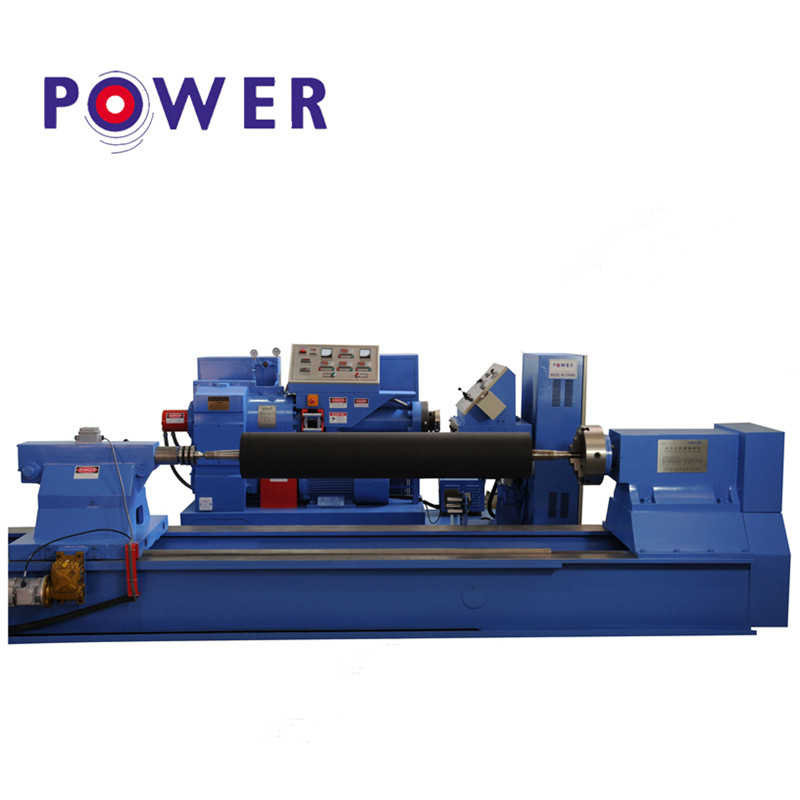

(3)The PTM-1580 & PTM-2010 models are suitable for processing big type paper mill, mine transmission and heavy industrial rollers.

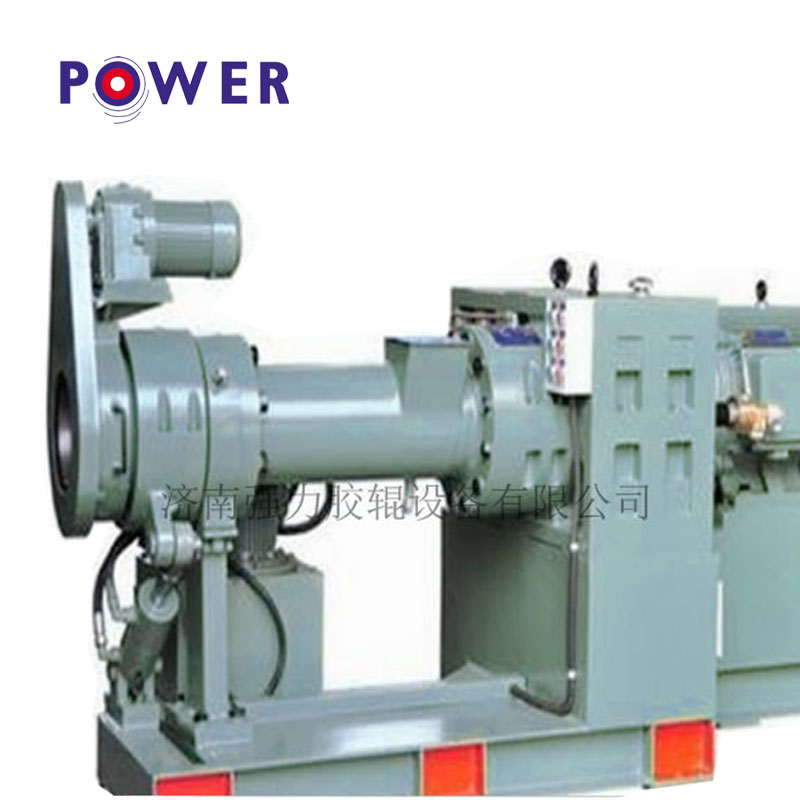

2. Equipped with E250CS, E300CS, E350CS or E400CS power extruder and a complete industrial cooling system.

3. Applicable to rubber compounding with all hardness range 15-100A.

4. Easy Installation with our professional technical support on-line or on-site.

5. Optional nylon type wrapping function, and other special design can be provided upon customer requirement.

| Model Number | PTM-4030 | PTM-8060 | PTM-1060 | PTM-1580 | PTM-2010 |

| Max Diameter | 16″/400mm | 32″/800mm | 40″/1000mm | 59″/1500mm | 79″/2000mm |

| Max Length | 118″/3000mm | 236″/6000mm | 236″/6000mm | 315″/8000mm | 394″/10000mm |

| Work Piece Weight | 500kg | 1500kg | 3000kg | 8000kg | 10000kg |

| Hardness Range | 15-100SH-A | 15-100SH-A | 15-100SH-A | 15-100SH-A | 15-100SH-A |

| Voltage (V) | 220/380/440 | 220/380/440 | 220/380/440 | 220/380/440 | 220/380/440 |

| Power (KW) | 25 | 45 | 55 | 75 | 95 |

| Extruder | E250CS | E300CS/E350CS | E350CS | E350CS/E400CS | E350CS/E400CS |

| Screw diameter | 2.5″ | 3″/3.5” | 3″/3.5” | 3.5″/4.0” | 3.5″/4.0” |

| Feeding Method | Cold feeding | Cold feeding | Cold feeding | Cold feeding | Cold feeding |

| Extruder Output | 4.2kg/min | 5.6kg/min | 6.6kg/min | 6.6kg/min | 6.6kg/min |

| Brand Name | POWER | POWER | POWER | POWER | POWER |

| Certification | CE,ISO | CE,ISO | CE,ISO | CE,ISO | CE,ISO |

| Warranty | 1 year | 1 year | 1 year | 1 year | 1 year |

| Color | Customized | Customized | Customized | Customized | Customized |

| Condition | New | New | New | New | New |

| Place of Origin | Jinan, China | Jinan, China | Jinan, China | Jinan, China | Jinan, China |

| Need of operator | 1-2 person | 1-2 person | 1-2 person | 1-2 person | 1-2 person |

Application

The automatic rubber roller covering machine is designed and produced for improving the rubber covering process. Appropriate models can be selected for different industries. Advanced and mature technology will bring higher efficiency to the roller production.

Services

1. On-site Installation service can be selected.

2. Maintenance service for life long.

3. Online support is valid.

4. Technical files will be provided.

5. Training service can be provided.

6. Spare parts replacement and repair service can be provided.

Product detail pictures:

Related Product Guide:

continue to improve, to ensure product quality in line with market and customer standard requirements. Our company has a quality assurance system have been established for Rapid Delivery for Surface Lapping - Rubber Roller Covering Machine – Power , The product will supply to all over the world, such as: Qatar, Peru, Holland, We've got constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. In depth Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Portugal for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.