In the vast and intricate landscape of polymer processing, where advanced machinery often captures the spotlight, the rubber strainer operates as a quiet, indispensable sentinel of quality. This robust and seemingly straightforward machine plays a critical role in ensuring the purity, consistency, and performance of compounded rubber, making it a cornerstone of reliable rubber goods manufacturing.

At its core, the function of a rubber strainer, or strainer-extruder, is filtration. Its primary mission is to remove contaminants—such as metal fragments, uncured rubber lumps, bagging fibres, or other foreign particles—from the compounded rubber mass before it is formed into sheets, pellets, or final shapes. The introduction of even minute contaminants can lead to catastrophic failures in finished products, causing weak spots, blowouts in tires, electrical failures in cables, or imperfections in medical seals. Thus, the strainer acts as the last line of defence in quality control.

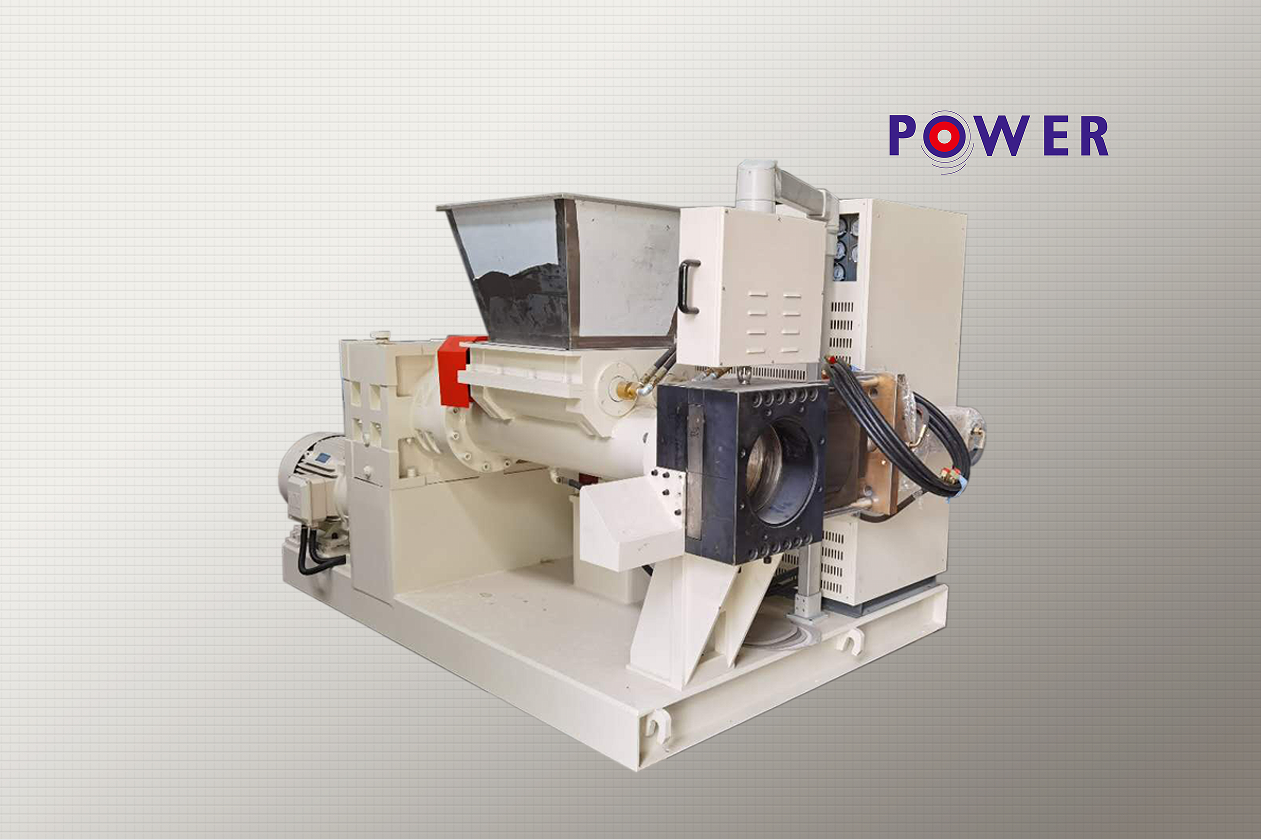

The machine’s design is elegantly purposeful. It typically consists of a sturdy extruder barrel equipped with a powerful screw. The compounded rubber is fed into the barrel, where the screw plasticizes and forcefully conveys it towards a crucial assembly: the breaker plate and the screen pack. The screen pack, a series of metal wire meshes with progressively finer gauges (often ranging from 20 to 100 mesh),lab kneader mixers, is the heart of the filtration process. As the pressurised rubber is forced through these fine screens, solid impurities are trapped. The filtered rubber then passes through a die head to form a continuous strand or a specific profile, which is then cooled on a conveyor.

Modern rubber strainers are engineering marvels built to withstand extreme conditions. They must handle high pressures, often exceeding 300 bar, generated by forcing viscous rubber through fine screens. To manage this, they feature robust construction with reinforced barrels and thrust bearings. A key innovation is the continuous operation capability. Early strainers required shutdown for manual screen cleaning. Contemporary models employ dual-piston or slide-plate mechanisms that allow the screen pack to be exchanged or cleaned without interrupting the flow, significantly boosting efficiency and consistency.

The applications of rubber straining are universal across the industry. It is vital in tire manufacturing for sidewall, tread, and inner liner compounds. High-performance technical goods like hoses, belts, and damping elements rely on strainers to ensure structural integrity. Perhaps most critically, rubber roller manufacturer,straining is non-negotiable in the production of medical, food-contact, and sanitary rubber products, where purity is paramount.

Beyond mere contamination removal,rubber covering machine, the strainer also contributes to product uniformity. The intense shear and pressure homogenise the rubber blend, ensuring a more consistent viscosity and dispersion of additives. This leads to improved processing in downstream operations like calendering or moulding, silicone roller covering strips for textile machinery,reducing waste and enhancing final product properties.

In conclusion, the rubber strainer is far more than a simple filter. It is a fundamental guarantor of safety, reliability, and quality in rubber manufacturing. Its relentless operation under punishing conditions ensures that the advanced materials developed in laboratories translate into trustworthy products in the real world. While it may lack the complexity of some downstream equipment, its role is irreplaceable—a true unsung hero, silently safeguarding the integrity of countless rubber components that form the backbone of modern transportation, industry, and daily life.

Post time: Feb-04-2026