Rubber mixing, also known as compounding or mastication, is the foundational process in the rubber industry. It transforms raw, viscous polymers into a homogeneous, processable compound with specific physical and chemical properties. This critical stage dictates the quality, consistency, and performance of the final product, whether it is a high-performance tire, a durable conveyor belt, or a medical seal. The process involves dispersing and distributing a complex cocktail of chemicals—such as fillers, softeners, activators, and curing agents—into the rubber matrix. To achieve this, the industry relies on a sequence of specialized machinery, primarily internal mixers, two-roll mills, rubber mixer,and downstream cooling equipment.

The Internal Mixer: The Workhorse

Modern high-volume mixing begins in the internal mixer, commonly associated with the Banbury® design. This machine resembles a high-intensity, sealed chamber. Its primary function is to generate intense shear and heat to break down the high molecular weight of the raw rubber (a process called mastication) and incorporate fillers like carbon black or silica.

The process begins with the operator feeding raw rubber—either natural or synthetic—into the mixing chamber. The chamber contains two specially shaped rotors that intermesh or operate in a tangential manner. These rotors rotate at slightly different speeds, creating a complex flow pattern that stretches, cuts, and folds the material. Immediately, internal mixer,heavy hydraulic or pneumatic cylinders lower a weighted ram into the chamber throat, material mixing mill,applying high pressure to the material. This ensures the compound is forced into the rotor tip clearances, maximizing shear.

As the rotors work the material, viscous dissipation generates immense heat. To prevent premature vulcanization (scorching), the chamber walls and rotors are equipped with a sophisticated temperature control system, circulating water or oil to maintain a precise temperature profile. The operator monitors the mix via a PLC (Programmable Logic Controller) , tracking the compound temperature and the total energy input (kWh). Once the desired dispersion state is reached—typically within 2 to 6 minutes—the mixer discharges the hot, dough-like batch through a drop door onto the downstream equipment.

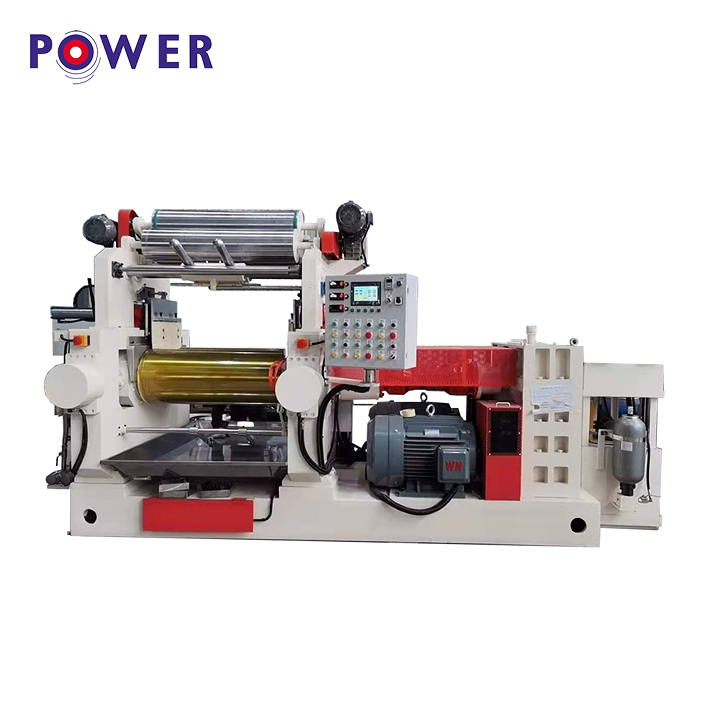

The Two-Roll Mill: Refining and Sheeting

Despite the prevalence of internal mixers, lab mill mixer,the two-roll mill remains vital. While used as a primary mixer for specialized compounds, its primary modern role is downstream of the internal mixer. The internal mixer produces a batch that is hot,rubber mixing mill process, loosely agglomerated, and difficult to handle. The mill refines this mass.

A two-roll mill consists of two parallel, horizontally mounted metal rolls rotating towards each other. They operate at different speeds (friction ratio), causing the rubber to adhere to the faster front roll. The hot compound from the mixer is fed into the “bank” (the nip where the rolls converge). As the material passes through the nip, it is subjected to immense shear and pressure. This action serves three purposes: it completes the dispersion of any remaining agglomerates, it cools the compound slightly through exposure to ambient air, and it forms the material into a thick, continuous sheet.

The operator uses tools to cut the sheet diagonally from the roll and fold it back onto itself (a process called “cutting and folding”). This ensures homogeneity and visual inspection of the mix quality. Finally, the sheet is stripped off the mill and fed into a batch-off system.

Downstream Cooling and Handling

The rubber sheet exits the mill at temperatures ranging from 90°C to 120°C. It cannot be stored in this state as it will stick together and continue to cure. Therefore, the sheet enters a batch-off cooler. This system utilizes a long, festooned conveyor where the sheet is passed through a dip tank containing a liquid release agent (typically soapstone or silicone slurry). This coating prevents adhesion.

The coated sheet is then carried via slat or mesh conveyors under high-velocity fans for forced-air cooling. Once cooled to below 40°C, the sheet is stacked neatly by an automatic stacker or wound into a roll on a winder. These stacked sheets or rolls are then labeled, staged, and sent for quality control testing before proceeding to the next manufacturing stage (such as extrusion or calendaring).

Auxiliary Equipment

The mixing room is supported by a host of auxiliary systems. Weighing and dosing systems are critical; carbon black is often pneumatically conveyed from silos to automated hoppers,dispersion kneader mixers, while small quantities of chemicals (curatives, accelerators) are weighed on high-precision scales and loaded into batch inclusion bags or automatic feeders. Dust collection systems are also mandatory in modern facilities to manage airborne particulates, particularly carbon black, ensuring worker safety and plant cleanliness.

In conclusion, rubber mixing is a precise science of heat management and shear force. It relies on the intense dispersive power of the internal mixer and the finishing capabilities of the two-roll mill. Without this specialized machinery—and the precise control systems that govern them—the raw gum rubber would remain a useless thermoplastic, never realizing its potential as a durable, elastic thermoset material.

Post time: Feb-12-2026