A rubber roller lathe-grinding machine is a specialized piece of industrial equipment designed for the machining, refurbishment, and maintenance of rubber-covered rollers. These rollers are critical components in numerous industries, including printing, paper manufacturing, textile processing, and steel production. The machine combines the functions of a traditional lathe and a precision grinder, allowing for both the turning (shaping) and grinding (finishing) of roller cores and their rubber surfaces to exact specifications. Its primary purpose is to restore the precise cylindrical geometry, surface finish, cnc cylindrical grinder manufacturers,rubber roller grinding machineand diameter of worn or damaged rollers, rubber roller surface grinding machine,ensuring optimal performance in their respective applications.

Key Components and Functionality

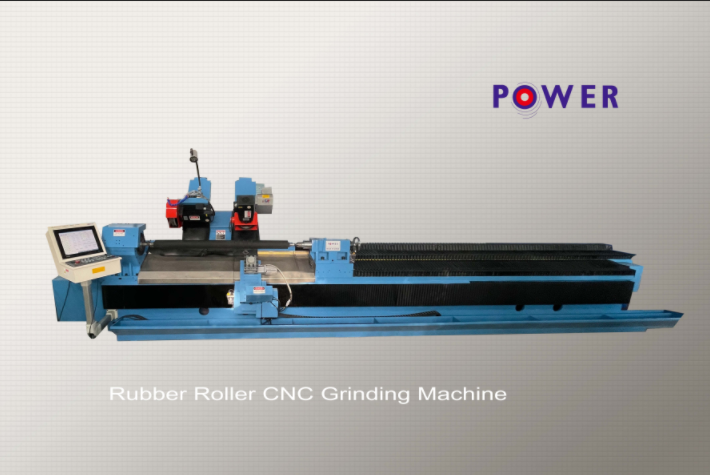

The machine typically consists of a robust bed, a headstock and tailstock to secure the roller between centers or in a chuck, a carriage that moves along the bed, and interchangeable tool posts. For turning operations, cutting tools are mounted to remove material from the metal roller core or to trim excess rubber after a re-covering process. The grinding functionality is provided by a high-precision grinding wheel mounted on a separate spindle, rubber roller surface grinder,often on the same carriage or a dedicated slide. A variable-speed drive system allows for optimal rotational speed (RPM) of the roller and appropriate feed rates for both cutting and grinding operations. Advanced models are equipped with digital readouts (DROs) or Computer Numerical Control (CNC) systems for exceptional accuracy in controlling dimensions.

The Typical Work Process

The process begins with mounting the roller securely between the centers. Proper alignment is crucial to avoid introducing runout. For a roller requiring re-grinding, the first step often involves a light turning pass to true up the rubber surface if it is heavily uneven or damaged. Following this, the grinding operation takes center stage.

The appropriate grinding wheel (typically vitrified bonded, with a grit and hardness suitable for rubber) is selected and dressed to ensure sharpness and cleanliness. Coolant, often a water-soluble type, is applied liberally during grinding. Its functions are multi-fold: to dissipate heat generated by friction (preventing thermal damage to the rubber, which can cause cracking or hardening), to wash away rubber swarf, and to lubricate the process for a better finish.

The operator sets the roller rotation speed and initiates a slow, steady traverse of the grinding wheel along the roller’s length. The depth of cut per pass is very fine, often just a few hundredths of a millimeter. This gradual material removal continues until the entire surface is uniform and the target diameter is achieved. The final stage involves achieving the required surface finish, which can range from a smooth glossy finish for printing rollers to a specific textured finish for paper handling rollers. This is controlled by the grit size of the grinding wheel and the feed rate.

Importance and Advantages

The use of a dedicated lathe-grinding machine is vital for several reasons. It ensures the roundness and concentricity of the roller, which is essential for vibration-free operation and uniform pressure across its width. It provides precise diameter control, critical for maintaining nip pressures in paired roller systems. Most importantly, it delivers a consistent, carbon fiber roller rubber roller manufacturer,high-quality surface finish tailored to the roller’s function—whether it needs to grip, release, transfer ink, or compress material.

Compared to manual methods or using standard lathes, these specialized machines offer superior accuracy, repeatability, and efficiency. They extend the service life of expensive rollers through multiple refurbishment cycles, significantly reducing operational costs for industries that rely heavily on roller technology. Proper operation and maintenance of these machines, therefore, are key to ensuring product quality and productivity in a wide array of manufacturing sectors.

Post time: Jan-23-2026