How to Choose one set Suitable Rubber Roller Covering Machine

In the world of rubber processing, the demand for high-quality rubber products is ever-increasing. One of the essential pieces of equipment in this industry is the rubber roller covering machine. This machine is crucial for producing rubber rollers used in various applications, from printing to manufacturing. With numerous options available, selecting the right rubber roller covering machine can be a daunting task. This article will guide you through the process of choosing a suitable machine, while also highlighting the importance of understanding how rubber is processed and the role of various manufacturers in the supply chain.

Understanding Rubber Processing

Before diving into the specifics of rubber roller covering machines, it is essential to understand how rubber is processed. Rubber processing involves several steps, including compounding, mixing, shaping, and curing. The rubber is first mixed with various additives to enhance its properties, such as durability, flexibility, and resistance to wear. This mixture is then shaped into the desired form using different machines, including rubber extruders and rollers.

The rubber extruder machine factory plays a vital role in this process, as it is responsible for shaping the rubber into strips or sheets that can be further processed. In China, there are numerous manufacturers specializing in rubber processing equipment, including those that supply high-quality long rubber strip feeders. These feeders are essential for ensuring a consistent supply of rubber material to the covering machine, which is crucial for maintaining production efficiency.

The Role of the Rubber Roller Covering Machine

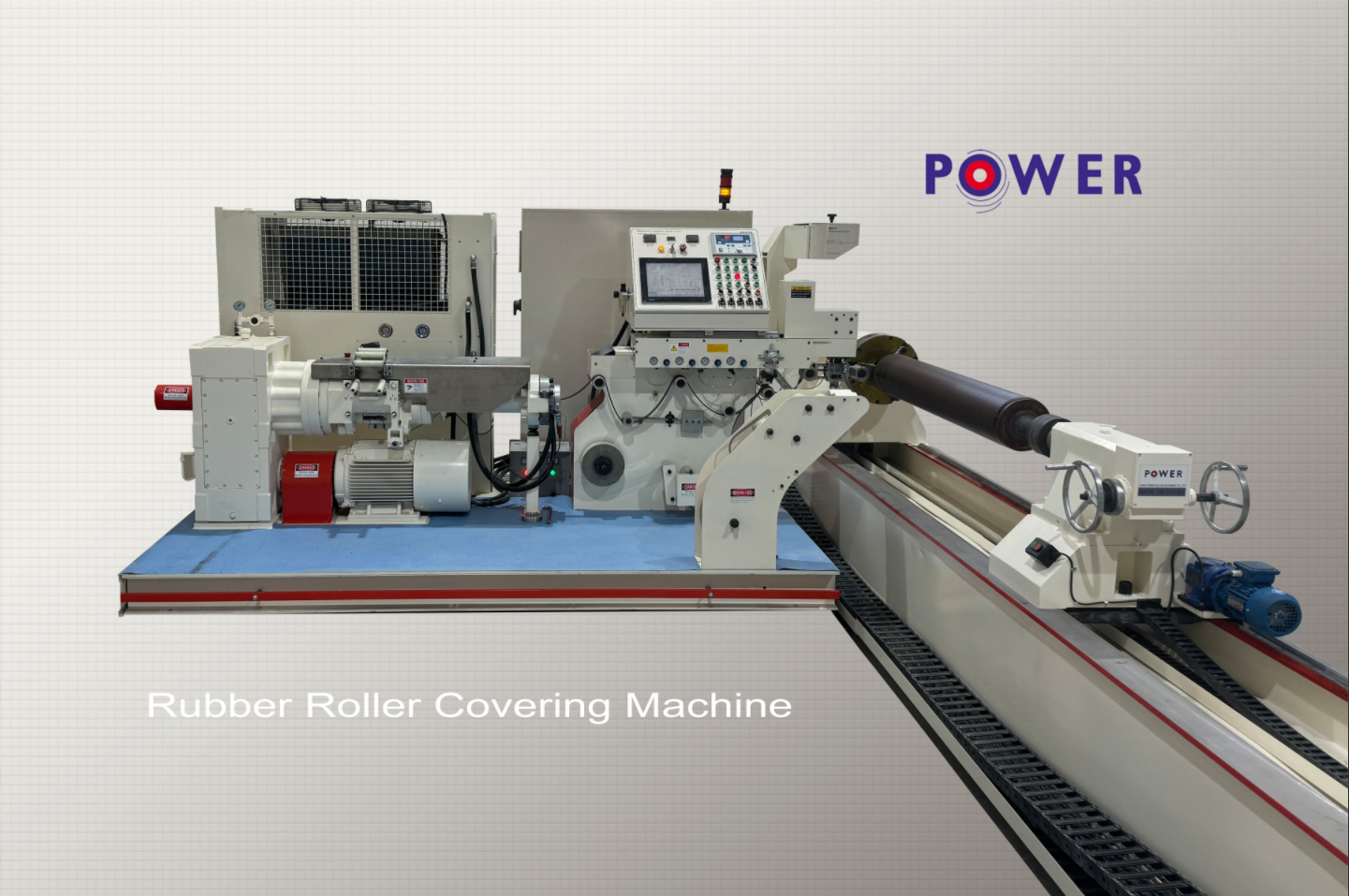

The rubber covering machine is the most flexible and convenient processing equipment for rubber roller production. It typically consists of several key components, including an extruder, covering device, constant temperature system, electric control system, and frame. Each of these components plays a critical role in the overall functionality of the machine.

1. Extruder: The extruder is responsible for shaping the rubber into the desired form. It ensures that the rubber is evenly distributed and free of air bubbles, which can compromise the quality of the final product.

2. Covering Device: This component applies the rubber to the roller, ensuring a uniform coating. The covering device can be adjusted to accommodate different roller sizes and shapes, making it a versatile option for manufacturers.

3. Constant Temperature System: Maintaining the right temperature during the covering process is crucial for achieving optimal results. The constant temperature system ensures that the rubber is processed at the correct temperature, preventing issues such as premature curing or uneven application.

4. Electric Control System: This system allows operators to monitor and control the machine’s various functions, ensuring smooth operation and minimizing downtime.

5. Frame: The frame provides the necessary support for the machine and its components, ensuring stability during operation.

Choosing the Right Rubber Roller Covering Machine

When selecting a rubber roller covering machine, several factors should be considered to ensure that you choose the most suitable equipment for your needs:

1. Industry Requirements

Different industries have varying requirements for rubber rollers. For example, the printing industry may require rollers with specific surface finishes, while the manufacturing sector may need rollers with enhanced durability. Understanding the specific needs of your industry will help you choose a machine that can meet those requirements.

2. Workpiece Sizes

The size of the workpieces you will be processing is another critical factor. Rubber roller covering machines come in various sizes and specifications, so it is essential to select a machine that can accommodate the dimensions of your rollers. This will ensure that you can produce rollers efficiently without compromising quality.

3. Production Volume

Consider the volume of production you expect to achieve. If you have high production demands, you may need a more advanced machine with higher throughput capabilities. Conversely, if your production volume is lower, a more basic model may suffice.

4. Manufacturer Reputation

When sourcing a rubber roller covering machine, it is crucial to choose a reputable manufacturer. In China, there are many roller processing manufacturers known for their high-quality equipment. Researching their track record, customer reviews, and product offerings will help you make an informed decision.

5. After-Sales Support

Finally, consider the after-sales support provided by the manufacturer. A reliable supplier should offer technical support, spare parts availability, and maintenance services to ensure that your machine operates smoothly over its lifespan.

Conclusion

Choosing the right rubber roller covering machine is a critical decision that can significantly impact your production efficiency and product quality. By understanding the rubber processing industry, the role of various components in the machine, and the specific requirements of your application, you can make an informed choice. Additionally, partnering with a reputable manufacturer in China that specializes in rubber processing equipment will ensure that you receive a high-quality machine tailored to your needs. With the right equipment in place, you can enhance your production capabilities and meet the growing demand for rubber products in various industries.

Post time: Jul-18-2025