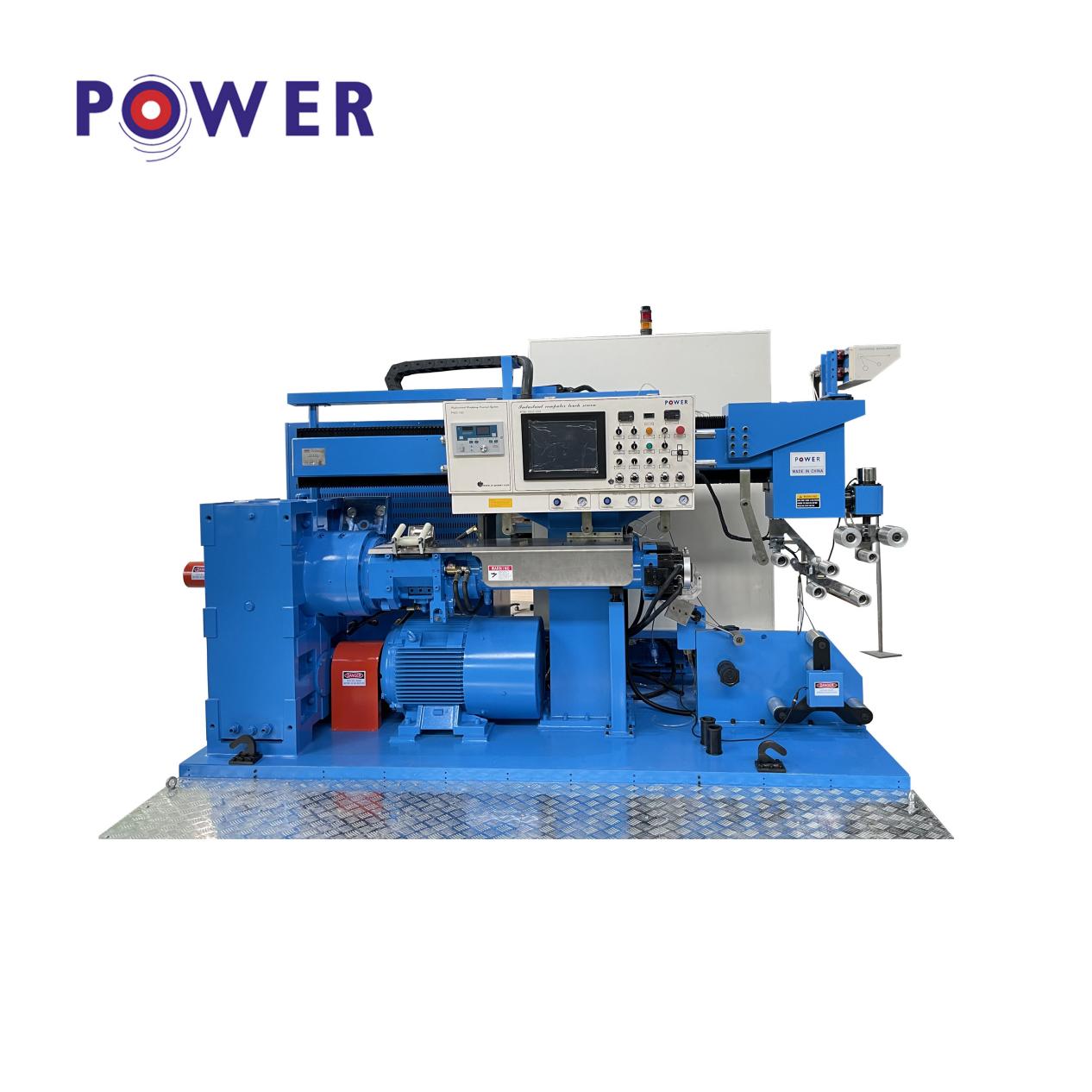

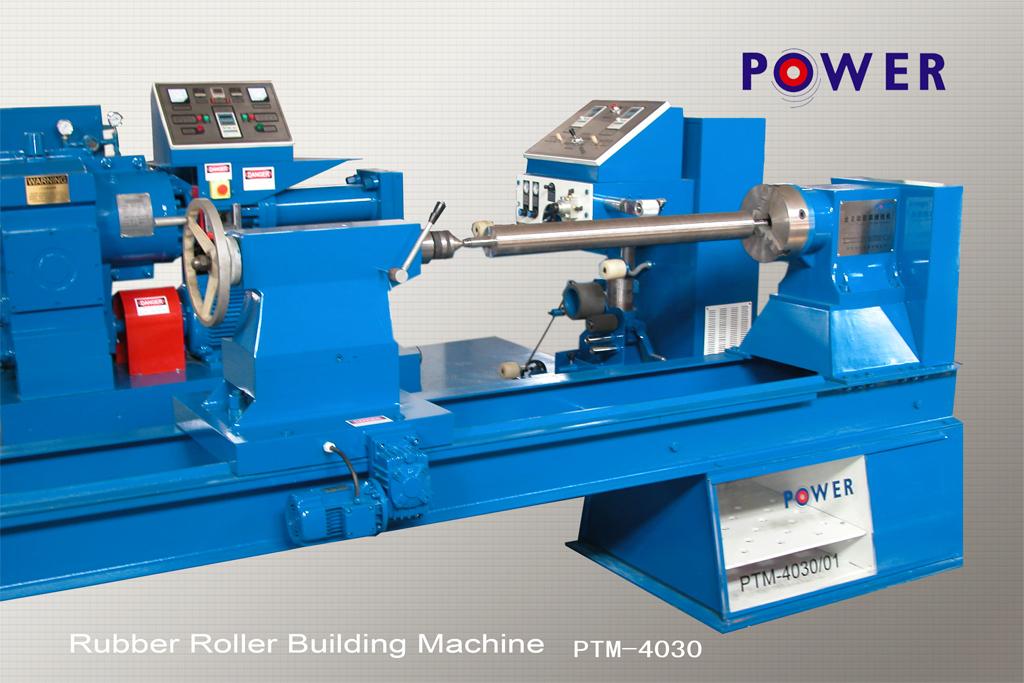

The automatic rubber roll covering machine is designed and produced to improve and improve the lagging process. Suitable models can be selected for different industries, and advanced and mature equipment will bring higher efficiency to your production.

Features of rubber roller covering machine:

1. It is suitable for the production of rubber rollers in the heavy industry, such as: steel and steel deep processing, textile, printing and dyeing and other industrial transmission rubber rollers.

2. Equipped with E300CS powerful special 76 cold feed extruder and a complete industrial refrigeration system;

3. Suitable for mixed rubber of various hardness;

4. The expansion of the coating function of the special parts of the rubber roller can be selected;

5. Generally, the printing rubber roller can produce 40-60 pieces per shift.

Possible problems and solutions of rubber roller covering machine.

The machine does not move when it is just started:

1. The main power supply is not connected Check the external power supply and re-power on

2. The control power supply is not connected. Use the key switch to turn on the power supply or close the switch in the power distribution cabinet.

3. Press the pause button and press it again to make it pop up

4. Press the emergency stop button and release the emergency stop button

5. The PLC is damaged and replaced

6. Reconnect the power cord and other equipment to the independent power supply

The turntable does not rotate:

1. The inverter is burnt, and the phenomenon is no display. Replace

2. The parameters of the inverter are set incorrectly. Set them again according to the requirements.

3. The chain of the turntable is broken. Adjust the distance between the large and small sprockets and connect the chain. If the chain is damaged, replace the chain.

4. The turntable motor itself is faulty. Use a multimeter or a shaker to check whether the motor is missing or broken down. If it cannot be repaired on site, replace the motor.

5. The turntable reducer itself is faulty, replace it

6. The knob is damaged and the chassis does not turn (E-type equipment) Replace

7. PLC has no output Replace

8. The connection between the turntable reducer and the sprocket is abnormal. Change the connection flat key

The turntable of the winding machine needs to be pushed to start:

1. The start time of the inverter slow start setting is too long. Reset it.

The turntable does not stop

1. The DIP switch is damaged. Overhaul the DIP switch.

The turntable cannot start or stop slowly:

1. The parameters of the inverter are incorrectly set. Re-set

There is a noise after the turntable turns:

1. The ground is uneven. The user is required to sort out or change the placement location.

2. Serious wear of individual supporting rollers Replace the supporting rollers

The inverter displays an overload alarm and the voltage is unstable. Improve the power quality or adjust the frequency conversion acceleration and deceleration time.

Damage to the active rubber roller and film frame connector (square rod):

1. If it is damaged during transportation, replace it

2. Artificially crashed and replaced

The film frame feeding speed can not be adjusted:

1. The DC speed control box is damaged and has no output. Replace it

2. The individual pallet wheels are seriously worn, and the supporting wheels should be replaced.

Post time: Aug-11-2022